Machinery & Equipment

Lab Equipments, Machines & Production Lines

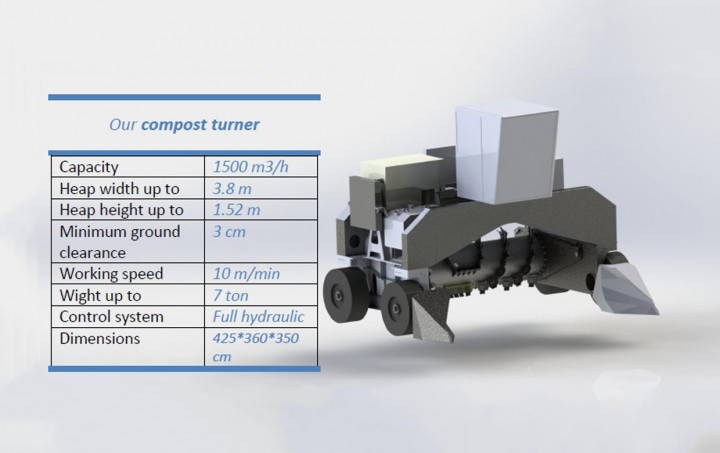

NAPCORP Windrows Compost Turner

The windrows are turned periodically with special turning machines to expose anaerobic volumes to oxygen. Turning also releases trapped heat, water vapor and gases and also mixes the materials, breaks up large particles and restores the pore spaces eliminated by decomposition and settling. Turning also exchanges the material from the outside of the windrow with that from the interior. This helps to ensure that all material receives equal exposure to the air at the surface and to the high temperatures inside the windrow thereby providing a uniform treatment process.

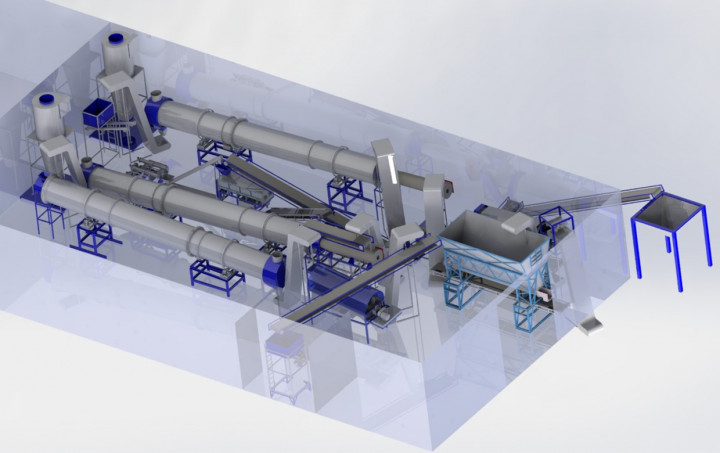

Smart Organic Fertilizer Production Line

The following equipment is used in natural organic fertilizer treatment and granulation and all are engineered and manufactured by NAPCORP. The proposed capacity of the machinery is 5 tons of organic fertilizer/ hour production line witch can be increased by repeating the machines. The total quantity output can be increased by adding shifts from one to two or three. In the single shift operation, the machinery can produce 13,200 ton/year of organic fertilizers (5 tons x 8 hours x 330 days). The output can be increased to about 40,000 ton/year by working 24h shifts, and employing extra staff.

GRANULATION MACHINE

Name : Granulator

Function : Converts the form of fertilizer into granules (small balls) of exact dimensions

Production capacity : 5 ton/h

Power consumption : 90 kW

Main dimensions : 6800x1500x2800

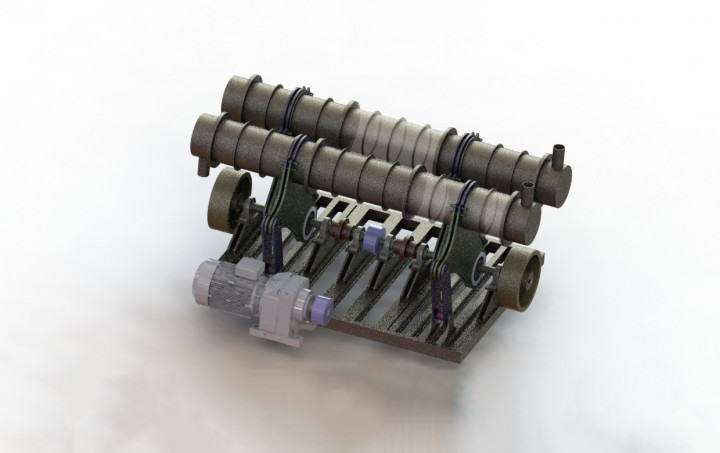

MIXING MACHINE

Name : mixer

Function : Mixing of compost components and additives as required and moisturizing (adding water) to prepare for the granulation stage

Production capacity : 5 ton/h

Power consumption : 11 kW

Main dimensions : 3500x1110x2550

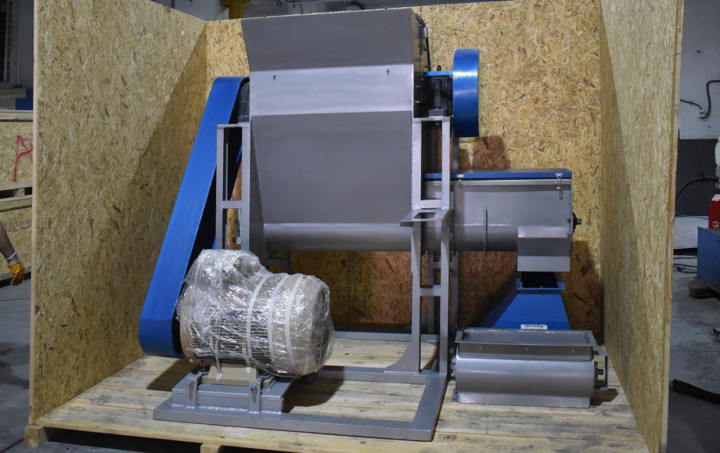

Hammer Mill

Name : Micro-size Mill.

Function : Initial milling of the compost to a microscopic particle size.

Production capacity : 5 ton/h

Power consumption : 55 kW

Main dimensions : 2200x1710x3060

Automatic Liquid Packaging Machine

Function : filling liquid products (normal and thick ), and can be customized for food and chemical industries.

Production capacity : up to 1 m3/h (differs by viscosity and bottle size ).

bottle size : 50 to 2000 ml

Power consumption : less than 1 kW including compressed air (6-8 bar).

Main dimensions : 270x185x202 cm

Storage Hoppers

Name : Storage hopper.

Function : Compost temporary storage and material flow regulation.

capacity : 10 ton

Power consumption : 3 kW

Main dimensions : 8000x2700x4600

Drying, sterilizing and cooling machines

Name : Dryer.

Function : Fertilizer drying (humidity reduction) and heat sterilization.

Name: Cooler.

Function: Cool the granulated fertilizer coming out of the dryer to prepare it for packaging.

Production capacity : 5 ton/h

Power consumption : 7.5 kW

Main dimensions : 20500x1750x3900

Conveyers

Name : Horizontal conveyor belt, Upward conveyor, and Screw conveyor.

Function : Transferring materials between different manufacturing stages and adjusting the flow and production rate.

Power consumption : 1.1 kW per conveyor.

Main dimensions : determined according to the production line and the nature and dimensions of the place of manufacture.

Packaging and weight

Name : Weight and packaging machine.

Function : Weigh and package compost in bags of different sizes.

Production capacity : 5 ton/h

Power consumption : – kW

Main dimensions : 2000x1700x3800

Size Separation machine

Name : Size Separation machine.

Function : Sort grain sizes before packing.

Production capacity : 5 ton/h

Power consumption : 1.1 kW

Main dimensions : 5800x1800x3400

Nano Mill

Name : Eccentric Ball Mill (ECBM).

Function : Milling the fertilizer powder to the Nano realm .

Production capacity : 5 ton/h

Power consumption : 45 kW

Main dimensions : 2200x1710x3060